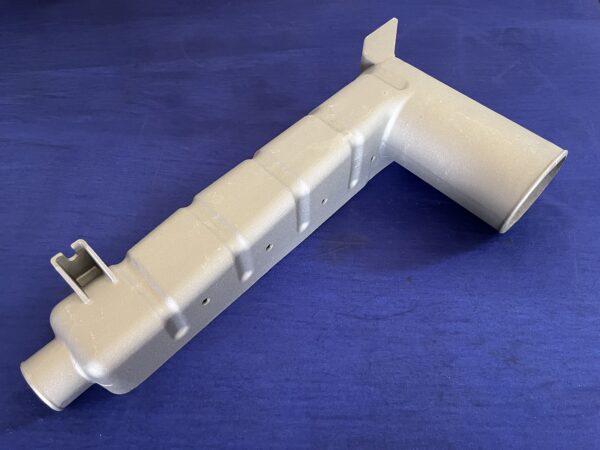

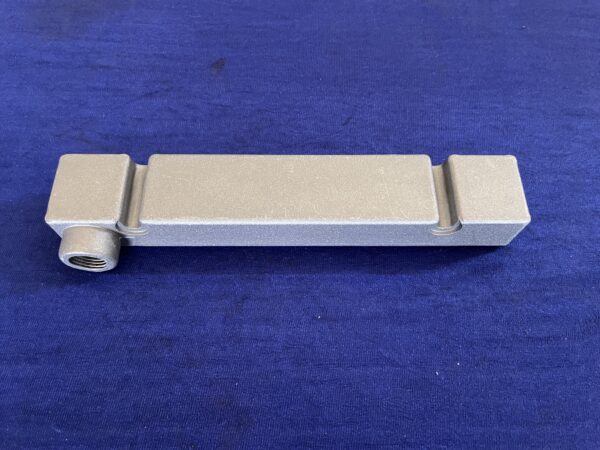

Gravity Die Casting

Gravity Die Casting is a metal casting process in which molten metal is poured into a mold that is positioned vertically/horizontally, allowing gravity to distribute the metal evenly into the mold cavity. This method is suitable for producing high-volume, complex-shaped parts with good surface finish and dimensional accuracy. Some common metals used in Gravity Die Casting includes aluminium alloys, The process is efficient and cost-effective, making it a popular choice for various industries, including automotive, aerospace, and electrical.